Flexible Combustion of Hydrogen Rich Fuels

A combustion solution that enables CO2 reduction and creates flexibility to the fuel balance of integrated production sites

H2 Combustion

Technology description

De Jong Combustion has developed conventional and duct burner solutions that are able to use a wide range of fuel gas mixtures including up to 100% v/v hydrogen.

- These combustion solutions allow the (partial) use of hydrogen on installations that require flexibility with regard to partial combustion of hydrogen

- This enables flexible hydrogen dosing to the NG grid and as such provides means to optimize the efficient use of green power for hydrogen production

- Technology is proven and implemented on HRSG’s, stand-alone boilers and process furnaces

De Jong Combustion is focussing its next generation hydrogen combustion burner developments on further reducing NOx emissions (with minimum flue gas recirculation) such that the transition to low/zero CO2 footprint hydrogen fuels in high duty, high temperature applications is not negatively impacting the environment with respect to increased NOx emissions.

Key features

- Non or partially pre-mixed combustion, reducing flashback risks

- Flexible solutions (green field and retrofits) allowing combustion of gas mixtures with 0- 100% v/v of hydrogen for duct burner and conventional applications (ref. list available)

- Within regulations concerning NOx emissions

Application fields

- De Jong Combustion duct burners that run on 0-100% hydrogen gas, are available > 100MW and are applied in HRSG’s and combined heat and power installations both as green field and retrofit projects

- De Jong Combustion fresh air, conventional burners that run on 0-65% hydrogen gas, are available up to 40 MW both as green field and retrofit projects.

- Processes: combustion and air drying processes

- Installations: HRSG’s, Combined heat and power (WKK’s), boilers, furnaces

- Used fuels: natural gas, refinery/process gasses, hydrogen (rich) gas

- Industries: power/steam plants, refineries, (petro)chemical plants, food and beverages, paper

Business case

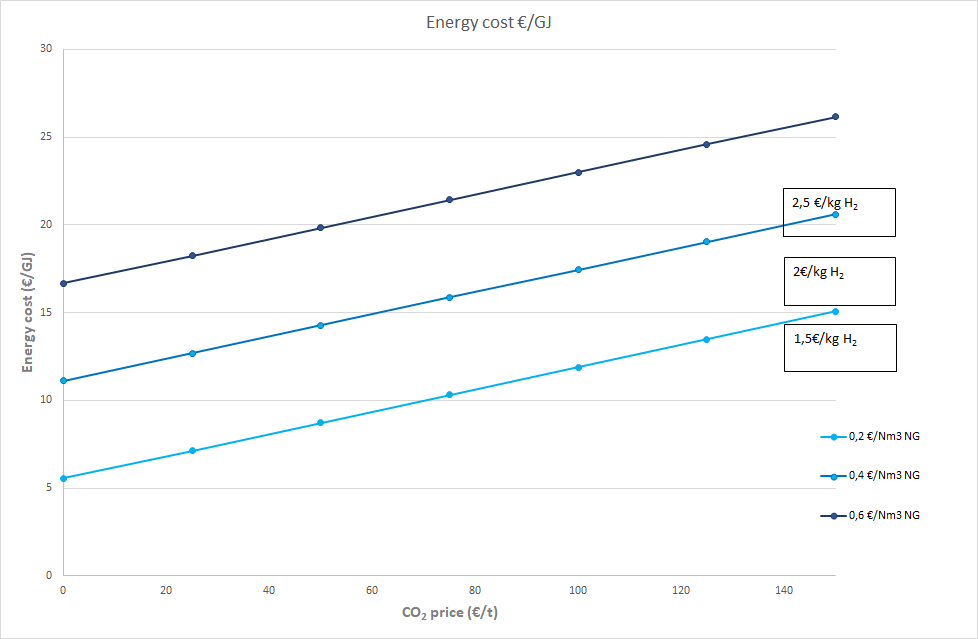

The economics for switching from natural gas to hydrogen firing depends on the actual cost of the existing energy source, the cost for hydrogen and the capital investment required to enable the fuel switch. In the graph attached an indication is given of this relation.

CO2 impact / Energy cost reduction

- Switching from 100% NG to 100% H2 saves ~50 kg CO2/GJ of NG energy used (85-90% SMR efficiency)

Non-energy benefits

- Fuel flexibility and fuel system balancing (i.e. for refineries and petrochemical complexes)

Technology deployed by

- Large industries and power plants in the Netherlands and abroad ( i.e.: Solvay, Akzo Nobel, DOW, GE)